Power Factor Correction capacitors are normally used to reduce induction in an electrical load, which minimises wasted energy and hence improves the efficiency of a company and reduces electricity costs. This helps to reduce the losses in the electrical supply to that equipment. Power Factor Correction (PFC) is used in some equipment to minimise the inductive component of the electrical current. This is bad news for the electricity generating companies who can impose a surcharge on heavy users if they have a consistently low Power Factor, as more electricity has to be produced to make up the shortfall.

This induction is caused by equipment such as small electric motors, fans, fluorescent lighting ballasts and transformers such as those in PSUs. Unfortunately in the real world, Power Factor is reduced by highly inductive loads down to values of 0.7 (70%) or less.

Ideally, Power Factor would be 1 (or 100%) and known as unity. “Power Factor” is a measure of how efficiently electrical power is consumed. If you are interested in being “green” and saving the planet, you might like to read a short explanation of how our power supplies can save energy using Active PFC (Power Factor Correction), not to be confused with Power Conversion Efficiency which is also very good in most of our PSUs. Please consider the above points very carefully before proceeding with an operation to replace the fan in your existing power supply! This can be a tricky operation to say the least.

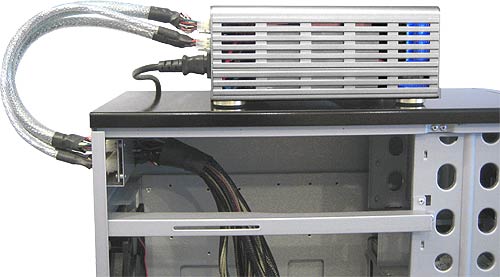

EXTERNAL POWER SUPPLY FOR COMPUTER PC

0 kommentar(er)

0 kommentar(er)